SmartBob

SmartBob is an accurate, highly reliable and proven inventory management system that can be utilized for monitoring the level of bulk solids and powders for one or an entire network of tanks, bins and silos.

SmartBob options include models for wireless communications, high or super-high temperatures, measuring submersed solids, and compatible consoles and Binventory software for monitoring data.

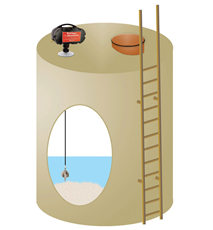

SMARTBOB SS for Submersed Solids

Model: SBR II SS

Image Credit: BinMaster

The SmartBob II SS sensor is a proven solution for measuring the level of solid material below a liquid surface and is a great alternative to relying on sight tubes. It can be utilized in tanks where solid material settles at the bottom of a tank.

Some application examples include:

- Chemical processing

- Wastewater facilities

- Brine tanks

- Water treatment

- Petroleum refining

- Food processing

- Salt and metal mining

The SmartBob-SS sensor’s special design includes a stainless steel cable that stands up to corrosive materials, a 3-inch standpipe for simple installation and a SureDrop cap, which stops the weight from being retracted into the pipe and protects the device from unwanted material entering through the standpipe.

SMARTBOBII Remote

Model: SBR II

Image Credit: BinMaster

The SmartBob II Remote is a reliable, proven, level measurement system that utilizes cable-based sensing technology.

Combined with remote control consoles and the powerful eBob software, SmartBob II provides the smartest, strongest cable-based inventory measurement system on the market. It has the ability to manage 1-255 bins as high as 150 feet.

SmartBob II can be configured uniquely using a range of probe designs, cables and special options for brine, slurry, solid and liquid applications. SmartBob’s cable cleaning system ensures hassle-free, long-lasting service.

SmartBob II is extremely rugged and features the strongest cable and motor design on the market, completely sealed in a lightweight, strong, molded polycarbonate enclosure that is explosion proof and rated for Class II, Groups E, F & G certifications.

SmartBob II is easy to install, requires no field calibration, needs minimal wiring or can be utilized with the SmartBob wireless transceiver.

SMARTBOB Multibob System

Model: SBR II MB

Image Credit: BinMaster

The SmartBob MultiBob inventory management system enables between 2 and 32 SmartBob sensors to be mounted in a single tank, bin, silo or any other vessel containing bulk solid materials or powders.

The advanced Binventory software is used to average the measurement data from all sensors and give a single level measurement and percentage full for the bin. There is more detailed data available to users about the material in their bin by taking and reporting measurements in multiple locations.

Measurement data, which is reported in feet or meters, is extremely precise and repeatable. Each SmartBob sensor measures in the same place each time, detecting level changes in bins containing difficult-to-measure material.

Common applications for MultiBob are grain bins such as 105’ or 130’ diameter, million bushel bins and bins with multiple filling and emptying points. MultiBob is also ideal for flat storage warehouses, covered storage bins and stockpiles where a single measurement is not adequate.

SMARTBOB AO with analog output

Model: SBR II AO

Image Credit: BinMaster

By simply installing the SmartBob on the top of the bin and wiring the sensor to the existing 4-20 input, the SmartBob AO with built-in 4-20 mA output and integrated keypad can replace any 4-20 device easily. The SmartBob AO automatically transmits an updated analog signal containing the measurement data to a PLC when it takes a measurement.

The SmartBob AO can be programmed to initiate a measurement using an internal timer to take readings at a predetermined time interval. An external start input can also be used to take a measurement immediately if required. To alert to measurement status or high, low, or error alarms, two configurable relay outputs may be used.

SMARTBOB for High Temperatures

Model: HT

Image Credit: BinMaster

The SmartBob II high temperature (HT) remote option is used for applications where the process temperature is between 240 °F and 500 °F. In order to extend the remote away from the heat source, a stainless steel standpipe is utilized and to keep the sensor probe out of the standpipe and level with the top of the bin, a stainless steel pipe extension fitted with a Teflon cable guide is used.

A standard air purge nipple enables a small volume of air to circulate through the mechanical cavity of the remote, helping it to stay at an acceptable operating temperature.

As per the standard SmartBob II remote, the SmartBob II high temperature model can be combined with remote push-button control consoles and a Windows-based Binventory software program to give a complete inventory management system for multiple brine slurry, solid and liquid applications.

SMARTBOB for Super High Temperatures

Model: SHT

Image Credit: BinMaster

The SmartBob II super high temperature (SHT) is used for extreme process temperatures, which are above 500 ˚F and not over 1000 ˚F. In order to extend this remote sensor away from the heat source, the SmartBob SHT includes a 36 ” long, 3 ” diameter galvanized standoff pipe.

To keep the sensor probe out of the standpipe and level with the vessel top a 1-¼ ” galvanized pipe extension, which is fitted with a bronze cable guide, is used. In the super high temperature option, all of the Delrin pulleys are replaced with aluminum pulleys.

The SmartBob SHT is designed for utilization with bare cable, plus either a stainless steel heavy spike bob or weighted 4 ” stainless steel inverted cone.

As the standard SmartBob II remote, the SmartBob II super high temperature model may be combined with Binventory software and remote push-button control consoles to supply a complete inventory management system for a range of slurry, solid and liquid uses.

SMARTBOB HM for Side Mounting

Model: SBR II HM

Image Credit: BinMaster

The SmartBob HM–for horizontal mount, an innovative version of BinMaster's proven SmartBob weight-and-cable based level sensor, can be utilized when it is not possible to install the sensor on the top of the bin.

The SmartBob HM has a custom-made, rigid, 12 ” to 36 ” long extension to install on the side of the bin through a 4 ” opening. Precise level measurements are performed at predetermined time intervals at a location directly below the probe to continuously monitor the inventory of material inside of the bin.

For a complete inventory management solution, SmartBob HM may be utilized in a mixed network of SmartBobs, which are installed on the top of the bin or are monitoring other materials.