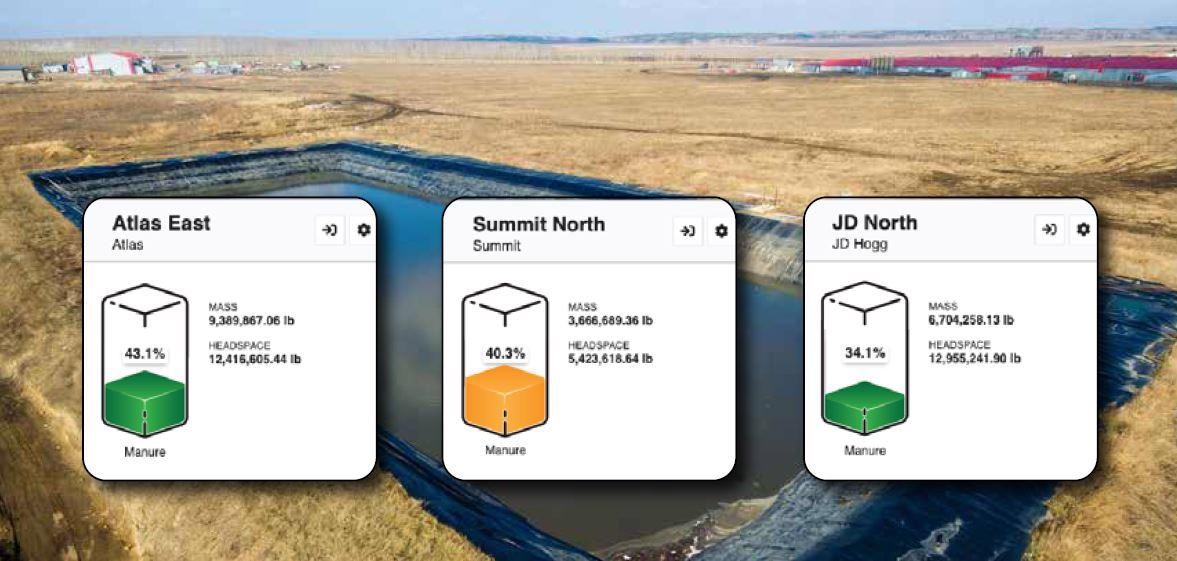

Pits and lagoons can be quantified, reports can be generated and historical trends can be viewed without using manpower. Waste volume can be monitored to improve fleet needs and application sites can be scheduled. Users can get text and email alerts and monitor historical data with the help of the PitView® feature in FeedView.®

Image Credit: BinMaster

Let PITVIEW® Help Users P&L

With a pit and lagoon monitoring system, users can save time while conforming to federal and state reporting and regulations, and thus minimize losses and boost their profits.

Keep a Clean Record

No animal feeding operation will prefer to risk a detrimental breach or spill their manure management system. Automating the tracking and reporting of waste levels make it simpler to create the documentation needed by regulators. Measurement history is effortlessly exported to reports that can be utilized for compliance with federal or state agencies.

Manage Application Sites

Users can automatically track pit and lagoon levels, and even set alarms to know when it is time to empty pits. PitView® enables users to plan application sites and schedule trucks well ahead of time. Users will know how much waste is available so that they can make arrangements for the manpower and equipment needed to get the job done.

Measurement Without Manpower

As soon as the level sensors are installed, the system comes into play. There is no need for anyone to go down to the pits or out to the lagoon to take measurements. Tracking occurs every day of the week, irrespective of staffing. If an alert is activated, staff are instantly alerted through email or text.

Monitor Waste and Feed-in One App

By introducing the PitView® feature to the FeedView® web application, users can track levels in lagoons, pits and feed bins, all in a single user-friendly program. Users can simply access the internet, log in using their username and password, and see all waste levels on their desktops, computer tablets, or smartphones.

How it Works

The CNCR-110 compact radar level sensor transmits a signal that quantifies the distance from the sensor to the waste material’s surface. The measurement is then sent to software with the help of a long-range wireless transceiver or cellular modem to a gateway, provided the facility has an Ethernet connection. Data can be accessed from the internet by logging into the secure FeedView® web application through a personal username and password.

Image Credit: BinMaster

View Pit, Lagoon and Feed Levels

Users can monitor pits and lagoons with the help of the PitView® feature available in BinMaster’s FeedView® web application. FeedView® is an extensive feed management solution that employs laser-level sensors to quantify levels in feed bins, create alerts and generate feed orders. Besides this, PitView® can be utilized as a standalone option or along with the feed management system.

Satisfy Regulatory Reporting Requirements

Data can be downloaded easily and reports can be created to conform to federal and state regulations. Producing interim reports for internal use enables users to watch trends and spot any unusual activity.

Set Measurement Frequency

Wired sensors, regardless of whether in a lagoon or a pit, are generally set to take measurements once an hour to once a day. At times, the solar-powered sensors that are utilized in lagoon applications are usually programmed to take measurements once a day.

Customize Alerts to Specific Operation

The software enables users to fix several alerts to help control lagoon and pit levels. Alerts are sent through email or text, allowing personnel to reply promptly if levels are detected in the danger zone.

Easy, Affordable, and Scalable

For pit and lagoon tracking, a one-time purchase of the mounting equipment and sensor is needed. After it is installed, there is a yearly tracking fee for every sensor. The software enables users to inspect various pits, lagoons, or sites with a help of a dashboard that consolidates measurement data in one place.

Image Credit: BinMaster

Non-Contact Radar is Rugged and Reliable

Radar-level sensors perform consistently in aggressive materials, harsh surroundings and even under adverse weather conditions.

The CNCR-110 is a flood-proof and robust non-contact radar developed for quantifying liquids at distances measuring up to 26 feet. The sensor is enclosed in an IP 66 or 68 enclosure, rendering it both dust and weather resistant to guarantee maintenance-free operation in animal waste.

Simple Sensor Installation

The sensor is mounted in a threaded 1½″ NPS bracket mount by merely screwing the sensor into place. The two-wire CNCR sensors can be effortlessly wired to a prevailing power supply. Alternatively, a solar-powered option is provided for lagoons in remote sites where electrical service is unavailable.

Accuracy Users Can Rely on

The sensor quantifies with a precision of 0.2″ in the static pit surrounding in which sensor mounting is attached. If the wind bounces the sensor or if the lagoon is choppy, the software will average various measurements.

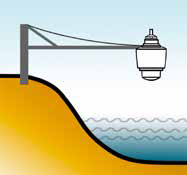

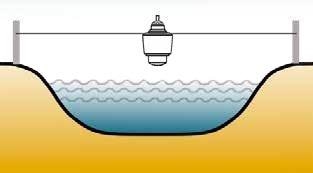

Sensor Mounting

Over Lagoon

Posts are positioned on both sides of the lagoon using the sensor mounted on a bracket connected to taut wires. Alternatively, a boom arm is fixed to a post. At the end of the boom arm, the sensor is mounted in a bracket, swinging across the lagoon and locking into place.

Image Credit: BinMaster

Image Credit: BinMaster

Sensor Specifications

- Accuracy: ± 0.2″ (± 5 mm)

- Measuring range: 26′ (8 m)

- Mounting: 1½″ NPT

- Housing material: PVDF plastic

- Process temperature: −40 to 60 °C (−40° to 140 °F)

- Ambient temperature: −40 to 60 °C (−40° to 140 °F)

- Process pressure: −1 to 3 bar (−14.5 to +43.51 psi)

Image Credit: BinMaster

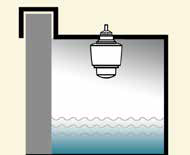

In Pits

A mounting bracket is secured to the pit wall using screws. The sensor is installed via the 1½″ opening in the bracket and is focussed at a 90° angle to the waste in the pit. The CNCR-110 wires to a power supply and is all set for operation.

Image Credit: BinMaster

PitView® Solves Problems with Pit and Lagoon Monitoring

Quantify pits and lagoons, produce reports and view historical trends without the help of manpower. The PitView® cloud application decreases the threat of a detrimental spill or breach of the manure management system.

PitView® automates the measuring and reporting of waste levels and enables users to view level data on a PC, tablet, or phone. It makes it simpler to prepare the documentation needed by regulators. Monitoring waste volume allows users to proactively improve fleet needs and plan application sites.

Each sensor location and the waste site have been exclusively named in the software. Alert conditions and measurement frequency-time intervals have been programmed for every sensor. If an alarm is activated, designated staff automatically receive an email or text enabling them to interfere before a breach takes place.

Reports can be run on demand for specific date ranges to view trends and comply with local regulations. PitView® makes use of a weather-tight non-contact radar level sensor to quantify pit and lagoon livestock waste at distances measuring up to 26 feet. It operates consistently in foam or turbulence. A flood-proof IP66/68 enclosure guarantees maintenance-free, constant operation.

For lagoons, posts are mounted on either side of the lagoon with the sensor placed on a bracket fixed to taut wires. An alternative lagoon mounting option is to suspend the sensor on a boom arm fixed to a post.

The sensor is wired to a power supply or alternatively, it can be powered by a solar panel. In pits, a mounting bracket fastens to the pit wall with the help of screws. The sensor is installed via a 1½″ opening in the bracket and is focused at a 90° angle to the waste in the pit.

As soon as PitView® is installed, there is no need for anyone to go down to the pits or out to the lagoon to take a measurement. Monitoring occurs every day of the week, email or text alerts are delivered even when staff are off-site. With PitView®, users can plan application locations and schedule trucks in advance. Users will know the amount of waste that is available so that they can arrange the manpower and equipment that is required to get the job done.

PitView® can even be added to BinMaster’s FeedView® cloud application to enable users to track levels in lagoons, feed bins and pits, all in a single, user-friendly program.