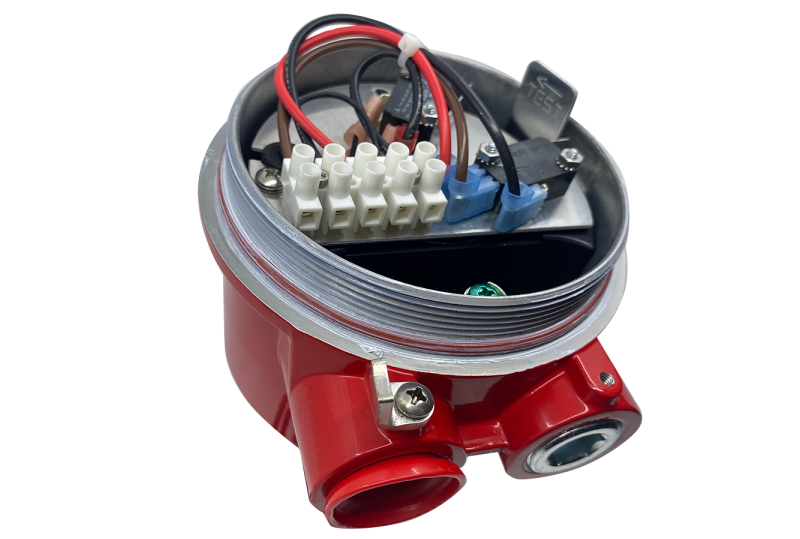

The innovative BinMaster BMRX-100 rotary level indicator is an electromechanical solution utilized in handling solid materials and powders, effectively preventing issues such as bin overfills, dry runs, or the need to halt a specific process.

What sets the BMRX-100 apart is its absence of printed circuit boards, rendering it impervious to the detrimental effects of moisture and vibrations frequently encountered in demanding processing environments.

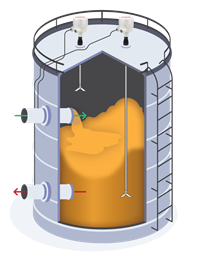

By continuously monitoring vessel conditions, whether they are full or empty, this device contributes to resource conservation and time-saving, particularly when managing bulk materials stored in various bins and silos. Its design accommodates materials with a bulk density ranging from 2 lb to over 100 lb per cubic foot under standard storage and processing conditions.

With its distinctive red enclosure, the BMRX-100 allows for post-installation rotation, ensuring conduit entries are consistently oriented toward the ground, effectively mitigating the risk of moisture-related damage to internal components.

Adding new wire guides guarantees that wires smoothly traverse conduit entries without obstructions.

Couplers and paddles are sold separately.

Image Credit: BinMaster

Image Credit: BinMaster

Overview

Rotary Paddle Switch: Point Level for Solids

The BMRX-100 represents a cost-effective paddle-style level switch designed to provide point-level alerts for solid materials and powders, catering to a wide range of bulk densities from 2 lb to over 100 lb per cubic foot.

Image Credit: BinMaster

Want to Prevent Overfilling Bins? Eliminate Dry Runs in Processing Operations?

Connect the BMRX-100 rotary to a light or horn for high or empty level alerts, and utilize the relay for initiating or halting processes like augers or conveyor belts.

Simple, electromechanical measurement for usual storage and processing operations.

Construction - Concrete and cement batch plants, silos of roofing granules.

Agriculture - Bins containing grain, seed, fertilizer, feed, or bulk ingredients.

Mining - Sand, aggregate, gravel, coal storage, and surge bins.

Plastics - Detect the level of plastic pellets in silos or hoppers.

Accessories for the BMRX-100

Paddles - Choose from 19 styles suitable for handling light, medium, and heavy bulk solid materials. Enjoy the convenience of collapsible paddles, allowing for installation without the need to access the vessel.

Mounting plates - Available in both carbon and stainless steel, these options come in 0°, 10°, 20°, and 30° angles, making them ideal for top mounting on sloped roofs.

Point level alarm panel - Delivers vessel level status through a flashing indicator light and audible alarm across 24 level indicator stations.

Quick disconnect - Eliminates the need for complex hardwiring, simplifying the installation and removal of the rotary device for cleaning, maintenance, or replacement.

Adjustable top mount - Adjust the high-level threshold using a movable coupling along a 72" shaft.

Applications

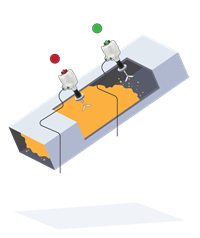

Overflow Prevention

High level alerts to prevent over-filling vessel

Image Credit: BinMaster

Material Outages

Low level alerts remove empty conditions

Image Credit: BinMaster

Plugged Chutes

Detect when chutes are clogged with material

Image Credit: BinMaster

Process Control

Utilize a switching relay to enable or disable a specific process.

Image Credit: BinMaster

Conveyor Overload

Avoid jamming or damaging conveyors

Image Credit: BinMaster

Specs

Source: BinMaster

| SKU |

BMRX-100.X1XAA |

| Means of Measurement |

Rotary Paddle |

| Measurement Type |

Point Level |

| Medium |

Solids |

| Voltage |

115 VAC |

| Outputs |

Relay SPDT |

| Ambient Temperature |

-40 °F to +185 °F (-40 °C to +85 °C) |

| Process Temperature |

Up to +176 °F (80 °C) |

| Approvals |

Unlisted |

| Enclosure Type |

NEMA 4X, IP 66 |

| Enclosure Material |

Die cast aluminum |

| Mounting |

1.25" NPT |

| Conduit Entry |

0.75" NPT |