Imagine removing climbing bins, depending on guesswork, piles of paperwork and massive spreadsheets. Instead, think of viewing feed inventory data on a computer, tablet, or phone.

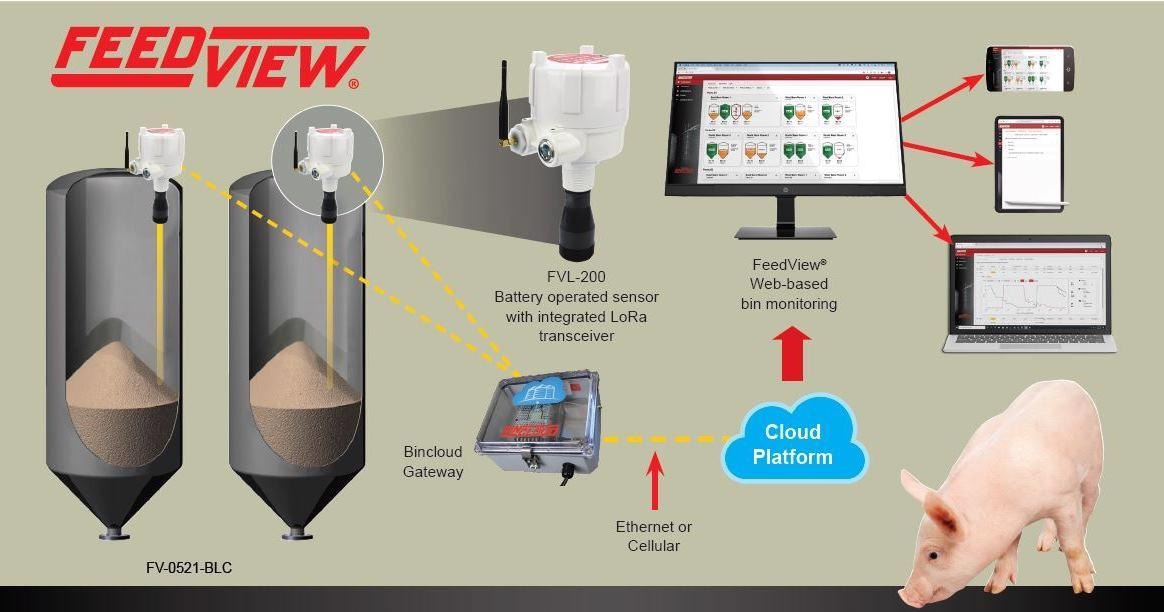

FeedView® is a complete feed management solution that integrates wireless, battery-powered level sensors with cloud-based, user-friendly software. Users can automatically quantify bin levels, project feed requirements with the help of historical consumption rates, record the application of medicated feeds and learn when to schedule deliveries anywhere and anytime using FeedView®.

Hog and Poultry Feed Inventory Transformed

FeedView® Software as a Service

BinMaster has specifically designed FeedView® for hog, cattle, or poultry operations. Operating in farms, personnel had conveyed their specific needs for tracking consumption, storage and delivery of feed together with the reporting required to simplify their job. FeedView® is cost-effective and fully scalable for a single barn to national producers.

Image Credit: BinMaster

Governing FeedView® begins with identifying feed groups, barns, farms and feed rations. FeedView® users are prepared for viewer or administrative roles for secure control over the system.

Every user can tailor their view with the columns of data they require. Corporate headquarters or feed mills can be granted access to data as preferred. This can prevent emails, spreadsheets and phone calls concerning inventory or delivery status.

Image Credit: BinMaster

Monitor Single or Tandem Bins

FeedView® can be easily adapted for tracking a single feed bin linked to a barn, or two or more silos feeding a barn simultaneously. This feature offers the option of automatically integrating the feed volume from two bins for operations alternating between two or more bins. Alerts are produced when the last bin supplying a barn is vacant.

Image Credit: BinMaster

FVL-200 FeedView Level Sensor

The battery-powered FVL-200 level sensor prevents the cost of wiring and streamlines setup, addressing the investment and installment concerns of feeding operations. The FVL-200 can be installed rapidly via a 1.5″ NPT connection with the help of a fixed angle mounting plate or an adjustable swivel mount.

The FVL-200 is powered by a Lithium battery and quantifies livestock feed in silos measuring up to 35 feet tall. It has a battery life of three to five years and takes interval readings once per hour.

LoRa long-range communications convey measurements to the FeedView web application for simple access from a desktop PC, tablet, or phone.

Image Credit: BinMaster

Revolutionize the Way Feed is Managed

Feed Groups

Livestock is positioned into feed groups depending on the feed bins from which they are feeding and are monitored across their processing cycle. Users can update the status of a feed group to consider headcount changes caused by death losses or sent to market. By using the status of the feed group and the average daily feed intake (ADFI) data, the consumption rate of the feed group is estimated and utilized to compute when bins will run out of feed.

Image Credit: BinMaster

Rations Management

Users can generate new rations, allocate them to particular feed bins and monitor if that ration was medicated (such as expiration dates and VFD numbers). The rations dashboard indicates which rations have been assigned to which bins. Historical records enable the user to assess when particular rations and medications were utilized and which bins they were assigned to.

Image Credit: BinMaster

Bin Details

A single click shows the specifics for a particular bin. A visual display shows the percentage the bin is filled with and the present alert status. It reveals the anticipated number of days until the bin will run out of feed and a prediction of how much feed will be present in the bin every day. The ADFI-based volume and headspace, the new sensor-measured volume and headspace, and the consumption rate of the feed group are displayed in tons per day.

Image Credit: BinMaster

A chart displaying sensor-level readings transformed to tons overlays the ADFI slope, denoting filling and consumption produced for a particular range of date. Charts can be made depending on other types of reading, such as distance, percent full, delivery capacity and the battery life of the sensor. Drilling down further, the latest sensor reading is time stamped, with reporting on all bin parameters.

Image Credit: BinMaster

Reports

Table and chart reports can be easily generated for the present status or a given historical reporting period. Rapid reports can be produced depending on a range of criteria, such as bins, farms, alert status, rations and reading type. Reports are effortlessly exported to Excel to share with others.

Feed Management Transformed

Sensors and Software Make it simple

Eliminate Feed Outages

Poultry, cattle, or swine operations can automatically quantify bin levels, predict consumption, record the application of medicated feeds and show when to plan deliveries.

Image Credit: BinMaster

Access Inventory Online

FeedView® can be accessed from a PC, tablet, or phone. Growers can make tracking and reporting of storage, consumption, and delivery of feed simpler and more efficient.

Image Credit: BinMaster

Feed Mill Coordination

Inventory visibility allows farms and mills to plan the production and delivery of required rations. Automated alerts through email or text notify when a barn is likely to become empty to decrease emergencies.

Image Credit: BinMaster

Wireless Level Sensors

Battery-powered FVL-200 sensors quantify livestock feed in silos measuring up to 35 feet tall. Measurements are delivered to the FeedView® web application for simple access from a PC, tablet, or phone.

Image Credit: BinMaster

Image Credit: BinMaster

Feedview® Helps Control Rising Feed Costs

FeedView® takes everything poultry and swine operations do with feed inventory and arranges it in a single simple software. It discards spreadsheets, manual measurements, and climbing bins. With just a single log-in, producers can view present levels, produce reports and place orders. Users can proactively avoid deficiency and delayed delivery charges by setting up automated alerts.

With the rising feed costs and the robust demand for pork, it is crucial to have just the right amount of feed on hand. Feed that is wasted affects profits. But FeedView® almost removes feed waste by estimating the amount of feed required until closeout. Besides this, it also saves on vacuuming and disposal charges.

Image Credit: BinMaster

Laser level sensors from BinMaster are powered by batteries, which make it easy to get started. As soon as it is connected to the gateway, readings are updated automatically in FeedView® SaaS from a desktop, tablet, or phone. These ever-evolving new features in FeedView® make feed management increasingly intuitive, easier and convenient.

Headcount: Headcounts can be adjusted for losses to make feed ordering more precise. Currently, headcounts can be simply edited on the main grid in-line rather than changing the barn setup.

User management: Offer visibility of inventory and orders to individuals who require it. Administrators can also add users, assign roles, set passwords, and enable particular users to create and place orders.

Custom dashboards: Users can easily generate a custom view by farm, ration, barn, or any other meaningful criteria. They can simply drag and drop columns where they want them to be displayed. Views are saved automatically for every user for upcoming user sessions.

Advanced sorting: Columns can be easily sorted in the grid view using a dropdown arrow and choosing the sort criteria. Users can also filter inside a column to rapidly get the information that they need.

Report generation: FeedView® safely stores inventory and order information and enables users to export purchasing or measurement history by a particular data range. Users can select the columns of data they prefer and export reports to MS Excel.

Delivered orders: Once the vessel is filled, orders are automatically labeled as delivered. There is no need to update the order or inventory status when making a delivery.