The in-line optical density sensor employs a blend of transmission and reflection measurements, ensuring consistent reliability across both low- and high-concentration scenarios. By utilizing a guided correlation model, a linear relationship between off-line and in-line measurements is established, guaranteeing precision throughout the process.

This advancement paves the way for enhanced process efficiency and potential automation in the future. While traditional control strategies remain applicable, this innovation also offers the opportunity to chart a fresh course for heightened productivity.

Source: Hamilton Process Analytics

| . |

. |

| 10064919-11 |

Dencytee RS485 120 |

| 10064919-12 |

Dencytee RS485 225 |

| 10064919-13 |

Dencytee RS485 325 |

| 10064919-14 |

Dencytee RS485 425 |

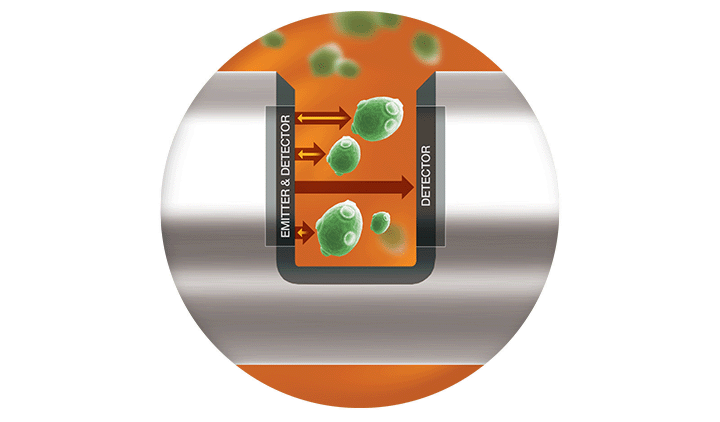

How Does Dencytee Arc Work?

Image Credit: Hamilton Process Analytics

Using the established 860 nm wavelength, the Dencytee Arc merges signals from both transmission and reflection into a reliable and reproducible measurement. This method consistently gauges the total cell density across an extensive concentration spectrum.

In our QbD-centered PAT ecosystem, which requires frequent adaptation to different bioprocess modes and R&D setups, we especially value the versatility and ease of integration of the Dencytee Arc system.

Lukas Neutsch, Head Bioprocess Technology, Zurich University of Applied Sciences