The OxyFerm FDA Arc polarographic dissolved oxygen sensors incorporate the hygienic design of the OxyFerm dissolved oxygen product line to enable direct analog and digital communication from the sensor, harnessing the advantages of Arc technology.

Source: Hamilton Process Analytics

| Part # / Ref |

Sensor

Family |

a-length |

Parameter |

Electrical

Connector |

Sensor

Output |

| 243100 |

OxyFerm FDA |

120 mm |

DO

(Electrochemical) |

VP8 |

Arc: Modbus,

4 to 20 mA |

| 243101 |

OxyFerm FDA |

160 mm |

DO

(Electrochemical) |

VP8 |

Arc: Modbus,

4 to 20 mA |

| 243102 |

OxyFerm FDA |

215 mm |

DO

(Electrochemical) |

VP8 |

Arc: Modbus,

4 to 20 mA |

| 243103 |

OxyFerm FDA |

325 mm |

DO (Electrochemical) |

VP8 |

Arc: Modbus,

4 to 20 mA |

| 243104 |

OxyFerm FDA |

425 mm |

DO (Electrochemical) |

VP8 |

Arc: Modbus,

4 to 20 mA |

| 243140-OP |

OxyFerm FDA |

56 mm |

DO

(Electrochemical) |

VP8 |

Arc: Modbus,

4 to 20 mA |

Accessories

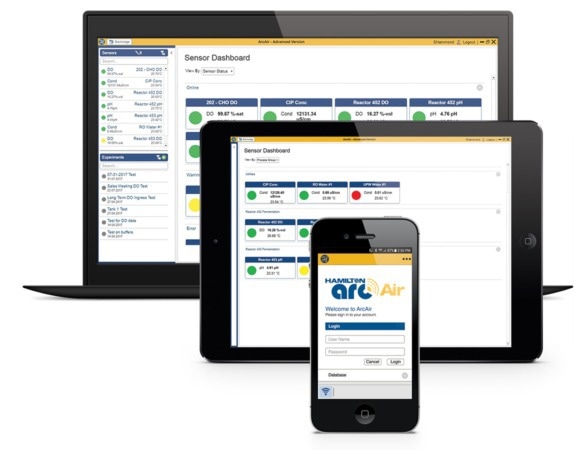

Arc Software and Accessories

Image Credit: Hamilton Process Analytics

ArcAir Software and wireless accessories can streamline common operations for Arc sensors, such as calibration and configuration.

Arc Sensor Cables

Image Credit: Hamilton Process Analytics

M12 or Variopin connectors are included with genuine Hamilton cables for Hamilton Arc sensors. The Arc sensor is programmed using these cables, which are also utilized for direct connections to the bioreactor or control system.

Polarographic Oxygen Maintenance

Image Credit: Hamilton Process Analytics

Kits, electrolytes, and associated components maintain the optimal operation of the OxyFerm or OxyGold dissolved oxygen sensor.

Specific Applications

Arc DO, pH, Cond in Production Scale Fermentation Process

At their GEA Diessel subsidiary in Hildesheim, Germany, GEA, a multinational equipment and process technology provider, incorporates Arc sensor technology in fermentation operations.