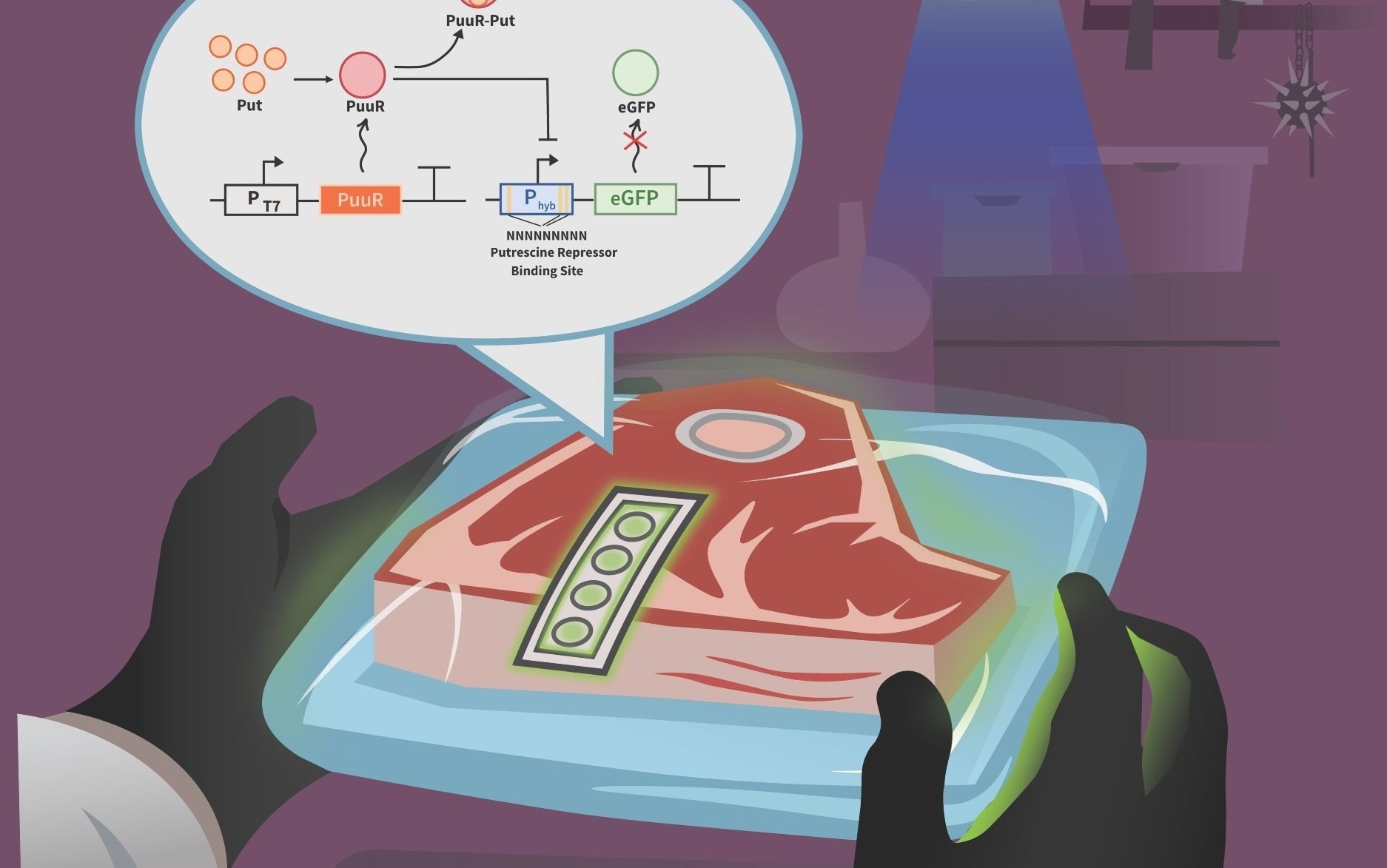

Researchers at the Shih Microfluidics Lab created a disposable, fast and reliable system for identifying putrescine in beef samples.

Georgia E. Perry. Image Credit: Concordia University

The supply chain that brings meat to market worldwide is highly complex and usually very efficient. But when disruptions in one part of the world can result in transportation delays an ocean and a continent away, meat spoilage becomes a very real risk to food producers, vendors, and consumers. This is especially true if food inspection protocols are lax.

To improve food safety, a group of Concordia researchers designed a new, inexpensive, reliable, and consumer-friendly technology that identifies the presence of the toxin putrescine in beef.

As its name denotes, putrescine is responsible for the noxious odors of putrefying meats, and, if consumed in large doses, can cause headaches, vomiting, diarrhea, and heart palpitations. It has also been linked to higher risks of colorectal cancer.

The researchers explain how they developed the paper-based synthetic biosensor in the journal Applied Bio Materials using a protein found in nature.

Making a rapid, easy-to-use biosensor for people to check the quality of the food they are eating is empowering. We wanted to make a device that anyone could use, that is disposable and contained no toxic materials.

Alaa Selim, Study Lead Author, Ph.D., Vaccine and Infectious Disease Organization, University of Saskatchewan

Alaa Selim's co-authors include her former Ph.D. student colleagues at the Shih Microfluidics Lab, James Perry, Mohamed Nasr, and Jay Pimprikar, as well as Steve Shih, associate professor of electrical and computer engineering.

Results Improve Over Time

The technique behind the sensor relies on cell-free protein synthesis, which produces a protein using the biological machinery of a cell without actually using the living cell. The researchers found that the putrescine repressor protein PuuR, found in the E.coli bacteria, could be used to indicate the presence of putrescine.

In a lab test, putrescine was added to the cell-free system that was producing the repressor in a solution and placed on a paper device to see if the researchers could visually see the presence of putrescine under UV light.

After an hour, the researchers found that the biosensor was detecting the presence of putrescine; after four hours, they were confident their readings were highly accurate.

They then proceeded to test actual meat samples. Small slivers of beef kept in a freezer, in a refrigerator, and at room temperature were compared to see how much putrescine accumulated over the span of several days.

As expected, the samples from the freezer and refrigerator had very low levels of putrescine, while the one kept at room temperature showed quite high levels—enough to sicken anyone who might eat it. They compared the results from their biosensor to those of high-tech chromatography used in food inspection and found their results to be somewhat correlated.

A Foundational Technology

While a fully functional, commercially available version of the biosensor will not be available any time soon, the researchers are optimistic about its potential.

We believe our work is a first step toward using sensors in the meat preparation industry. In addition, we believe this type of sensing can be used for other fields like environmental sampling of heavy metal contamination and cancer and disease diagnostics.

Steve Shih, Associate Professor, Electrical and Computer Engineering, Concordia University

Steve is also the Chair in Microfluidics for Biological and Chemical Analysis.

For Selim, the most important thing to a consumer is their health and the health of their family. “I want anyone, regardless of their background in technology, to be able to use this, whether it’s a college student, a busy mom or people working in the restaurant industry.”

This research received funding from the Natural Sciences and Engineering Research Council of Canada, SynBioApps NSERC CREATE program, the Fonds de recherche - Nature et technologies, and the Canadian Foundation of Innovation.