Aug 20 2010

The enhanced utilization of laser sensors in component positioning or geometric calibration ensures quality protection even without shifting the objects that need to be analyzed.

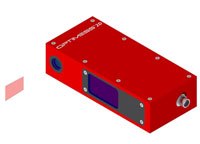

2D OPTImess laser sensor

2D OPTImess laser sensor

The novel 2D OPTImess light section sensor indicates a further progressive innovation of the OPTImess 1D series. In this type, the laser beam is dilated to a line, and a two dimensional calibration along the laser line is obtained by sourcing it to a CCD matrix. detector The two dimensional OPTImess can be widely used in railways which permits the measurement of the head of the rail, wheel contours , rail cants and track width without disturbing the sensor.

The size of the laser sensors is in the order of 200mm x 90mm x 50mm, with a calibration range of 300mm and line length of 150mm. The sensor monitors the entire calibration or measuring process.

The information about the recorded measurement values in the laser line order can be obtained from the output itself, which eliminates the need for an external controller limiting the length of the cable.