It is vital to measure, actuate, record, and control to efficiently operate a process. ABB offers the best measurement solution for customer’s needs, allowing maximum return on investment. ABB measurement solutions and products provide the best technology, service, and reliability in the business.

An essential source of ABB’s technology leadership is its research and development. For new applications, ABB continuously builds on the foundation of current technologies, and to meet the challenges of the future, it continues to develop breakthrough technologies. For over 100 years, ABB and its heritage companies have provided leadership in innovation and technology.

Comprehensive Measurement Solutions Serving Any Industry

For over a century, ABB measurement products have been offering world-class measurement solutions for any utility, industry, or municipality.

To enable easier operation of a plant, modern innovations provide technological solutions. Common technology forms the basis for ABB measurement products to offer a standard look and feel and method of operation.

The resulting products are easy to integrate, configure, and maintain.

ABB Measurement Products Portfolio

ABB offers the following products:

- Analytical measurements

- Pressure measurement

- Flow measurement

- Natural gas measurement

- Temperature measurement

- Level measurement

- Force measurement

- Valve automation

- Recorders and controllers

- Device management

- Service

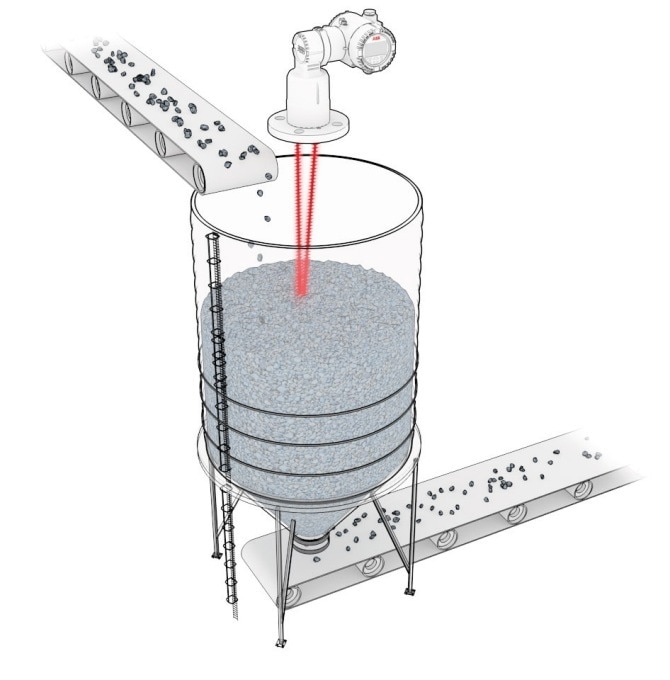

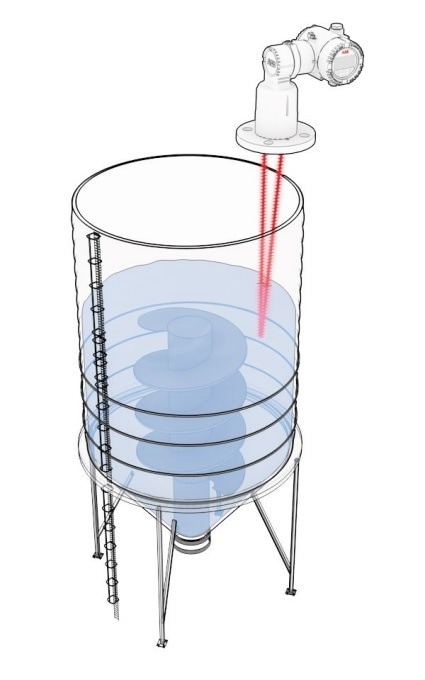

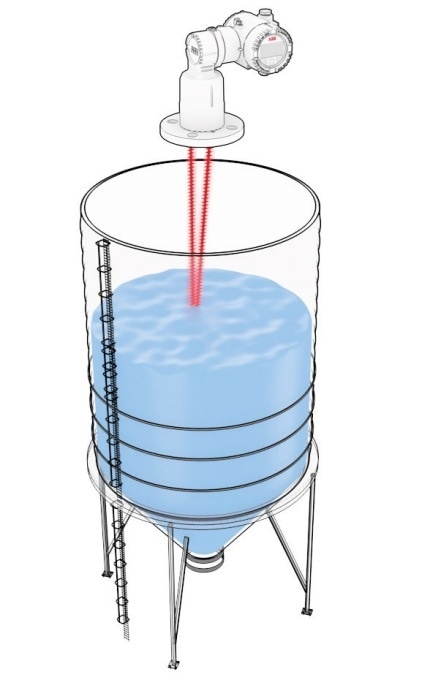

Non-Contact Level Measurement Solution

Accurate and reliable level measurements can be easily made with the ABB family of non-contact laser level transmitters. Laser level measurement has transformed the level measurement industry. The transmitter can be used in all industrial applications replacing open-path radar and other level transmitters. It will redefine the way users conduct level measurement. In other words, it is measurement made easy.

Industries Served

- Aggregates

- Chemicals

- Fertilizers

- Mining and construction

- Pulp and paper processing

- Power generation

- Food and beverage

- Oil and gas

- Water and wastewater

Customer Benefits

- Very accurate

- Rapid response

- Non-contact

- Range up to 200 m

- Maintenance free

- No echo mapping needed

- Narrow beam unaffected by surrounding structures

- Flexible installation, can be aimed at an angle

Level Measurement with Laser Technology

The LM80, LLT100, and LM200 use a time-of-flight calculation to accurately measure the distance to the target surface.

Invisible, eye-safe, infrared laser pulses are used by these level transmitters to measure the distance to the surface. The transmitter has an on-board microprocessor that measures the distance by multiplying the known speed of light by the laser pulse travel time from the transmitter to the surface and back.

Very little divergence (<0.3°) in the laser beams enables easy and accurate targeting even in vessels or silos having internal structures. In addition, the narrow beam does not build-up on vessel walls or interact with local structures, making the measurement extremely reliable even if there is a change in the environment. This eliminates reconfiguration and down-time, and reduces lifetime costs.

Made for Industrial Applications

- Measures through fog and dust

- Certified for high pressures

- Approved for hazardous areas

LM80 and LM200 – Intermediate and Long Range Laser Level and Position Transmitter

LM80

The non-contact, laser level measurement transmitter LM80 has been specifically designed for opaque liquids and solid materials. It is based on pulsed laser technology, and embodies accuracy and speed in an easy-to-use and install product.

The laser’s characteristic narrow beam divergence allows direct aiming to the target surface without any interference from falling material or structure.

The LM80, with single point relay and continuous 4-20 mA outputs, can work as a process control sensor and at the same time provides low and high alarms.

Whether users are measuring a few meters to the bottom of the tallest silo, or into the limited space of a crusher, the LM80 with its laser pointer provides a perfect plug-and-play solution to level measurement.

Options

- Configuration device (LCD2)

- Many mounting options

- Dust tube

- Stainless steel housing

- Non-condensing optics (heated lens)

LM200

The LM200 laser level measurement transmitter is specifically designed for long range applications. It can measure opaque liquids at distances up to 45 m / 148 ft and solids at distances up to 200 m / 656 ft. It is used in many applications such as ore pass level monitoring in mining, for example.

The LM200 is perfect for long distance positioning applications up to 400 m, provided a reflector is used on the targeted object. For example, this can be employed for tripper car positioning, offering a maintenance-free solution, and since the sensor never makes contact with the moving car, it will not wear.

Options

- Dust tube

- Configuration device (LCD2)

- Non-condensing optics (heated lens)

- Many mounting options

- Reflector panel for positioning application (available for all laser level transmitters)

LLT100 – The New Standard in Industrial Laser Level Transmitters

The LLT100 is the new generation of laser level measurement transmitters. It builds upon the success of the LM80 model and features a host of advanced technologies to customize laser time-of-flight measurement according to the needs of industrial applications.

The LLT100 can therefore measure any solids or liquids, including transparent liquids, by using powerful signal processing, precise timing circuits, and laser pulse control. The level liquids can be measured at up to 30 m (100 ft) and solids at up to 100 m (330 ft). All these capabilities are integrated in a single 2-wire powered device.

The LLT100 is supplied with a wide range of process interfaces that are standard in the industry:

- Standard aluminum or stainless steel flange

- Hygienic triclover flange

- High pressure flange

Being Certified for Use in Gas and Dust Hazardous Areas

The LLT100 has been specifically developed for harsh industrial environments. It offers non-contact, continuous level measurement capabilities for inventory management and process automation in many industries such as aggregates, chemicals, oil and gas, food and beverages, mining, power, pharma, pulp and paper, and water and waste water.

Customer Benefits

Optimize Process or Inventory Management

- Independent of material properties

- Precise measurement of any liquid or solid

Low Cost of Ownership

- Single product configuration works for many applications

- No reconfiguration required when there is a change in the environment

- Fast and flexible installation

Convenient

- Easy setup menu

- 2-wire powered and HART 7 communication

- Orientable embedded graphical user interface

Reliable

- Accurate measurement at distances up to 100 m (330 ft)

- Fog and dust penetration capabilities

- Approved for use in hazardous area class 1, division 1 (zone 1)

Multiple Accessories

Dust tube

Swivel flange

Cooling tube

A wide range of accessories is available to complement the LLT100, LM80 and LM200 laser level transmitters, and help address specific environments and different applications.

Common accessories are:

- Dust tube – Prevents dirt or splashing liquids on the window

- Heated window – Prevents condensation on the window

- Rotating (pivot) bracket – Perfect for aiming the laser beam

- Swivel flange – Provides precise aiming of the laser beam and is particularly useful in liquid applications

- Cooling tube – Increases maximum process temperature to 280°C/535°F

- Purge ring – Enables the LL100 dust tube to be air purged

- LLT100 Laser pointer tool – Used to visually align the position of a bracket prior to installing the LLT100

Heated window

Rotating Purge ring (pivot) bracket

LLT100 Laser pointer tool

Purge ring

The Solutions Meeting Your Industry Needs

| |

LM80 |

LM200 |

LLT100 |

| Product category |

Non-contact level measurement |

|

|

| Range |

Level up to 100 m (330 ft)

Positioning up to 150 m (500 ft) |

Level up to 190 m (623 ft)

Positioning up to 400 m (1312 ft) |

Level up to 100 m (330 ft)

Positioning up to 200 m (655 ft) |

| Laser |

Measuring 905 nm Infrared Laser Class 1M

Pointer 635 nm red Laser Class 3R |

|

Measuring 905 nm Infrared Laser Class 1 |

| Resolution |

± 10 mm (0.4 in) |

|

± 5 mm (0.2 in) |

| Accuracy |

± 30 mm |

± 40 mm |

± 20 mm |

| Temperature |

-40 °C to +60 °C (-40 F to +140 F) |

|

|

| Power |

24 VDC (3 wires) |

|

24 VDC (2 wires)

24 VDC (4 wires) when using heated window option |

| Outputs |

Analog output 4-20 mA

2 relays

RS232 for configuration |

|

HART v7 |

| Enclosure type |

Aluminum

Stainless steel |

Aluminum |

Aluminum

Stainless steel |

| Process pressure |

Atmospheric |

|

-1 to 50 bars depending on process flange |

| Enclosure rating |

IP66/Nema4X |

|

IP67/Nema4X |

| Certifications |

CE

ATEX

IECEx

cCSAus

FM |

CE

ATEX

IECEx

cCSAus

FM |

CE

ATEX

IECEx

FM

3-A

CRN |

This information has been sourced, reviewed and adapted from materials provided by ABB Level Measurement Products.

For more information on this source, please visit ABB Level Measurement Products.