Analytical devices called in-line dissolved oxygen sensors are made to continuously monitor DO levels for a variety of industrial processes, providing real-time data. The robust yet straightforward design of industrial dissolved oxygen probes guarantees precise measurement under all process circumstances.

METTLER TOLEDO provides in-line DO sensors for applications in pure water, microelectronics, and the food and beverage, chemical, and power industries to guarantee that all specifications are satisfied.

Sensor PureWater ISM Optical DO

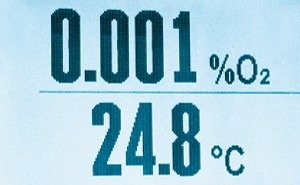

In demanding low ppb-level dissolved oxygen measurement applications, the METTLER TOLEDO Pure Water Optical DO Sensor with Intelligent Sensor Management (ISM) technology offers excellent accuracy, quick response, and stability.

- Measurement Parameter: Oxygen

- Measurement Technology: Optical fluorescence quenching

- Measurement Range: 0-5000 ppb

- Primary Media/Application: Semiconductor Water, Power Plant Water/Steam

Image Credit: Mettler Toledo - International

DO Sensor InPro6860i/12/120/mA/HD

The InPro 6860i/12/120/mA/HD is an optical dissolved oxygen sensor featuring a mechanically modified hydrophilic surface. Its tilted design and the prevention of bubble accumulation result in a very stable measurement signal.

- Measurement Parameter: Oxygen

- Measurement Range: 0…saturation

- Measurement Technology: Optical fluorescence quenching

- Primary Media/Application: Pharmaceutical/Life Science Production

Image Credit: Mettler Toledo - International

DO Sensor InPro6860i/12/220/mA/HD

Measurement Parameter: Oxygen

- Measurement Range: 0…saturation

- Measurement Technology: Optical fluorescence quenching

- Primary Media/Application: Pharmaceutical/Life Science Production

Image Credit: Mettler Toledo - International

DO Sensor InPro6860i/12/320/mA/HD

Measurement Parameter: Oxygen

- Measurement Range: 0…saturation

- Measurement Technology: Optical fluorescence quenching

- Primary Media/Application: Pharmaceutical/Life Science Production

Image Credit: Mettler Toledo - International

Increased Reliability Through ISM Technology

Predictive diagnostics is used by in-line DO sensors equipped with Intelligent Sensor Management (ISM) technology to track sensor maintenance requirements for increased process availability and efficiency.

Image Credit: Mettler Toledo - International

Accurate In-Line DO Probes with Low Detection Limits

In-line DO sensors from METTLER TOLEDO are ideal for brewing and pure water because they consistently deliver dependable measurement accuracy, even at trace, ppb-level detection limits.

Image Credit: Mettler Toledo - International

Quick In-Line DO Sensor Start-Up

ISM in-line DO sensors with plug-and-measure technology enable sensor calibration in a controlled setting away from the process. This allows measurement points to start up quickly and accurately.

Image Credit: Mettler Toledo - International

In-Line DO Sensor Technology to Meet User Requirements

There are two types of METTLER TOLEDO in-line DO sensors: optical and amperometric. Various membrane materials make it possible to have the appropriate in-line DO probe for the process.

Image Credit: Mettler Toledo - International

Measurement for a Range of Industrial Processes

In-line DO sensors offer accurate DO measurement for processes in biotechnology, pharmaceutical development, brewing, chemical manufacturing, and water purity monitoring.

Image Credit: Mettler Toledo - International

Low Maintenance with Predictive Diagnostics

In-line DO sensors' straightforward design makes maintenance simple and painless. Additionally, predictive diagnostics alerts users to necessary maintenance before measurement is compromised.

Image Credit: Mettler Toledo - International

Hygienic Design for Clean Environments

Certain in-line dissolved oxygen sensors are made for use in sanitary settings. They can be autoclaved and steam sterilized to meet industrial standards for traceability and hygienic design.

Image Credit: Mettler Toledo - International